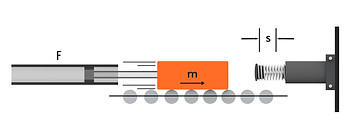

Sizing Industrial Shock Absorbers for Mass With Propelling Force

Industrial shock absorbers play a critical role in safely decelerating moving masses influenced by external forces. This guide explains how to size shock absorbers for cases where a mass is propelled by an external force.

CALCULATION CONCEPTS

-

Kinetic Energy (W1): The energy possessed by a moving mass due to its velocity.

-

Formula: W1 = 1/2 * m * v^2

-

Significance: This is the primary energy that the shock absorber must dissipate to bring the moving mass to a complete stop.

-

-

Propelling Energy (W2): Propelling energy is the energy used to drive or push an object forward.

-

Formula: W2 = F⋅s

-

Energy added by the external force FFF acting over stroke s.

-

-

Total Energy Per Stroke (W3): In the presents of external propelling forces, the total energy to be absorbed by the shock absorber is equal to the kinetic energy of the moving mass.

-

Formula: W3 = W1 + W2

-

-

Load Factor: The ratio of the total energy per stroke (W3) to the shock absorber's maximum allowable energy capacity.

-

Formula: Load Factor = (W3 / W3per) * 100

-

Recommendation: For optimal performance and durability, the load factor should ideally be below 80%.

-

-

Impact Speed (vD): The velocity of the mass at the moment of impact with the shock absorber. In this case, it is equal to the initial velocity of the moving mass (v).

-

Effective Mass (me): The equivalent mass experienced by the shock absorber during deceleration. It ensures smooth deceleration over the entire stroke length.

-

Formula: me = W3 / (1/2 * v^2)

-

Note: The effective mass must fall within the shock absorber's specified permissible range.

-

-

Deceleration Time (t): The time required to bring the moving mass to a complete stop.

-

Approximate Formula: t ≈ 2.6 * s / vD

-

Note: Shorter deceleration times generally result in higher forces on the shock absorber.

-

-

Supporting Force (Q): The force exerted by the shock absorber to decelerate the mass.

-

Formula: Q = 1.5 * W3 / s

-

Note: The structure to which the shock absorber is mounted must be adequately designed to withstand this force.

-

-

Cycles Per Hour (x): The number of impacts the shock absorber experiences within one hour.

-

Formula: x = 3600 / (t_reset + t)

-

Note: The actual number of cycles per hour must not exceed the shock absorber's maximum permissible cycles per hour (xper).

-

SIZING PROCEDURE

-

Gather Input Data:

-

Mass of the object (m) in kilograms.

-

Velocity at impact (v) in meters per second.

-

Desired stroke length (s) in meters.

-

Number of cycles per hour (x) in impacts/hour.

-

-

Calculate Total Energy Per Stroke (W3): Use the formula W3 = 1/2 * m * v^2.

-

Determine Effective Mass (me): Calculate me using the formula me = W3 / (1/2 * v^2) and ensure it falls within the acceptable range for the shock absorber.

-

Estimate Deceleration Time (t): Calculate t using the approximate formula t ≈ 2.6 * s / vD.

-

Verify Supporting Force (Q): Calculate Q using the formula Q = 1.5 * W3 / s and ensure the mounting structure can withstand this force.

-

Check Load Factor and Cycles Per Hour:

-

Calculate the Load Factor and ensure it is below 80% for optimal performance.

-

Verify that the actual cycles per hour (x) do not exceed the maximum permissible cycles per hour (xper) for the shock absorber.

-

Example Calculation

-

Given:

-

Mass (m) = 36 kg

-

Force (F) = 400N

-

Velocity (v) = 1.5 m/s

-

Stroke Length (s) = 0.025 m

-

Cycles/hours (n) = 1000

-

-

Step 1: Calculate W1:

-

W3 = 1/2 * 36 kg * (1.5 m/s)^2 = 41 Nm

-

-

Step 2: Calculate W2:

-

W2= 400 x 0.025 = 10 Nm

-

-

Step 3: Calculate W3:

-

W1+W2=41+10=51Nm

-

-

Step 4: Calculate W4:

-

E4=W3 x n =51⋅1000=51,000Nm/hour

-

-

Step 5: Calculate me:

-

me = 2 x 51/1.5² = 48 kg

-

-

Step 6: Calculate: t = 1.52 x 6 x 0.025 = 0.043 seconds

-

Step 7: Calculate: Q=1.5 x 51/0.025 = 3,060N

Note: This is a simplified guide. For precise sizing, consider factors like operating temperature, environmental conditions, and specific shock absorber characteristics.